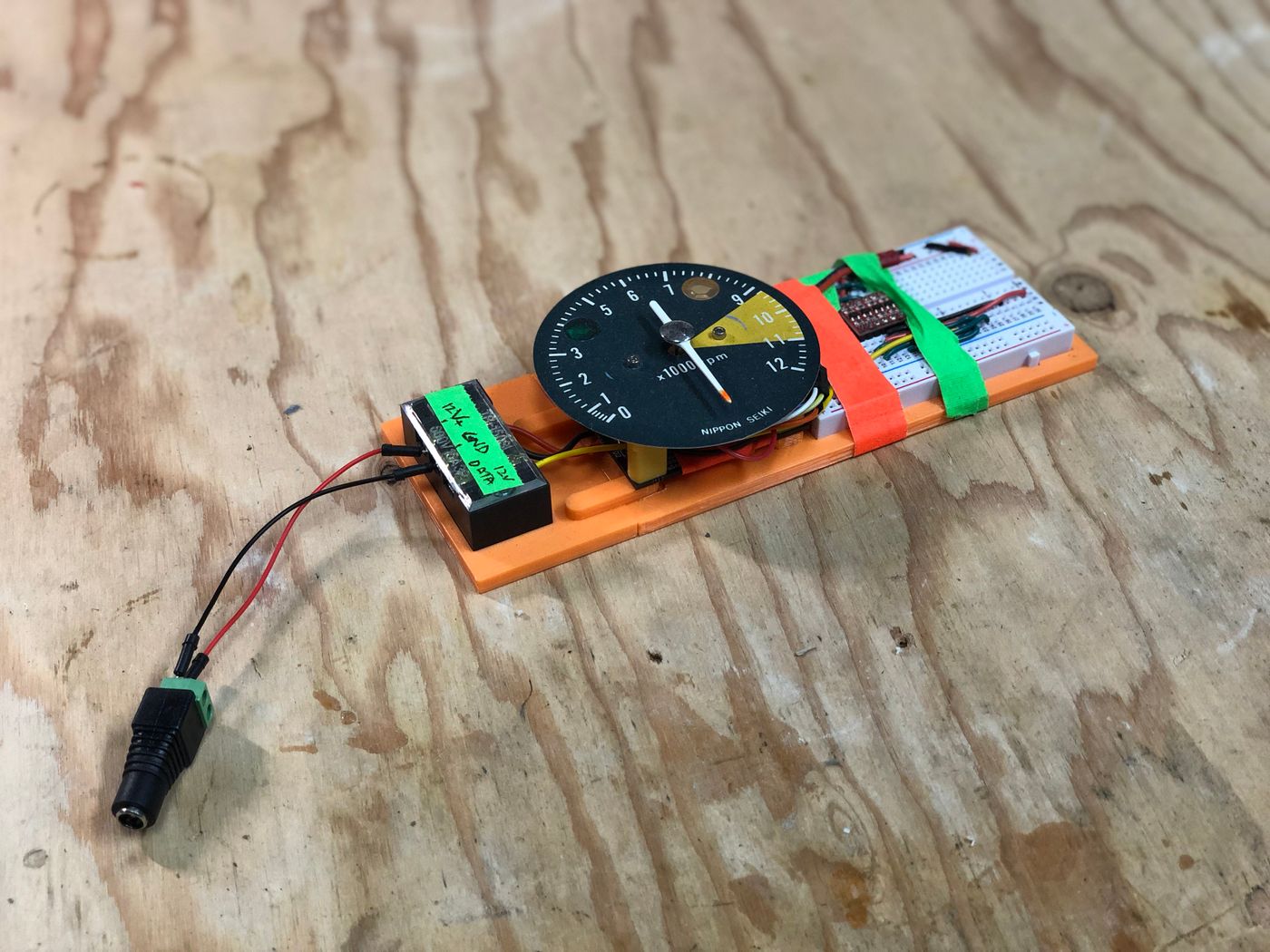

CB350 Digital Tachometer conversion

CB350 Tachometer - Analog to Digital conversion

While building my cafe-style CB350, I knew from the very beginning that I wanted to stick with using the OEM tachometer that came with the bike. There is a certain elegance about those tachometers that I didn’t want to change.

However, those tachometers relied on a mechanical drive from the engine. That meant a bulky cable that was prone to wearing out and failing.

So I started to wonder if I could keep the aesethetic of the tachometer, but give it modern internals. So that kicked off this project.

Dimensions

- Faceplate is 75mm diameter, sheet metal is 0.5mm thick (with paint, about 0.53mm)

- Hole for needle mounting rod is 5mm and exactly at center of faceplate.

- Faceplate mounting holes are 25mm apart center-to-center. Holes are ~2mm, and M2 machine screws can be used.

- Faceplate mounting holes and center hole are in an exact line through the center of the faceplate.

- Turn signal indicator light is 10mm diameter, and composed of transparent green plastic.

- Neutral light indicdator is also 10mm diameter and composed of clear or pale yellow plastic (unclear if yellow is from age)

- Determine angle of total sweep area (from 0 RPM to 12000 RPM)

- Detmine angle and depth of center point of both indicator lights

Digital Conversion

- Disassemble the enclosure and remove all contents.

- The speedometer needle can be removed safely and without damage by taking two spoons and placing them opposite of each other with the edge of the spoon under the fat center of the needle. Press down on the handles of spoons so that the bottom of the spoon is pressing down on the faceplate, and the tip of hte spoon is “lifting” on the needle. With firm pressure, the needle should break loose from the rod.

Components to retain

- Enclosure (top and bottom part)

- Rubber gasket for enclosure

- Tachometer faceplate.

- Tachometer needle

New Components

- Switec X27 stepper motor (easily found on ebay sold as gauge cluster replacements)

- 3D printed parts for new brackets/assembly

- Particle Photon

- 12V -> 5V stepdown converter

- Logic level shifter